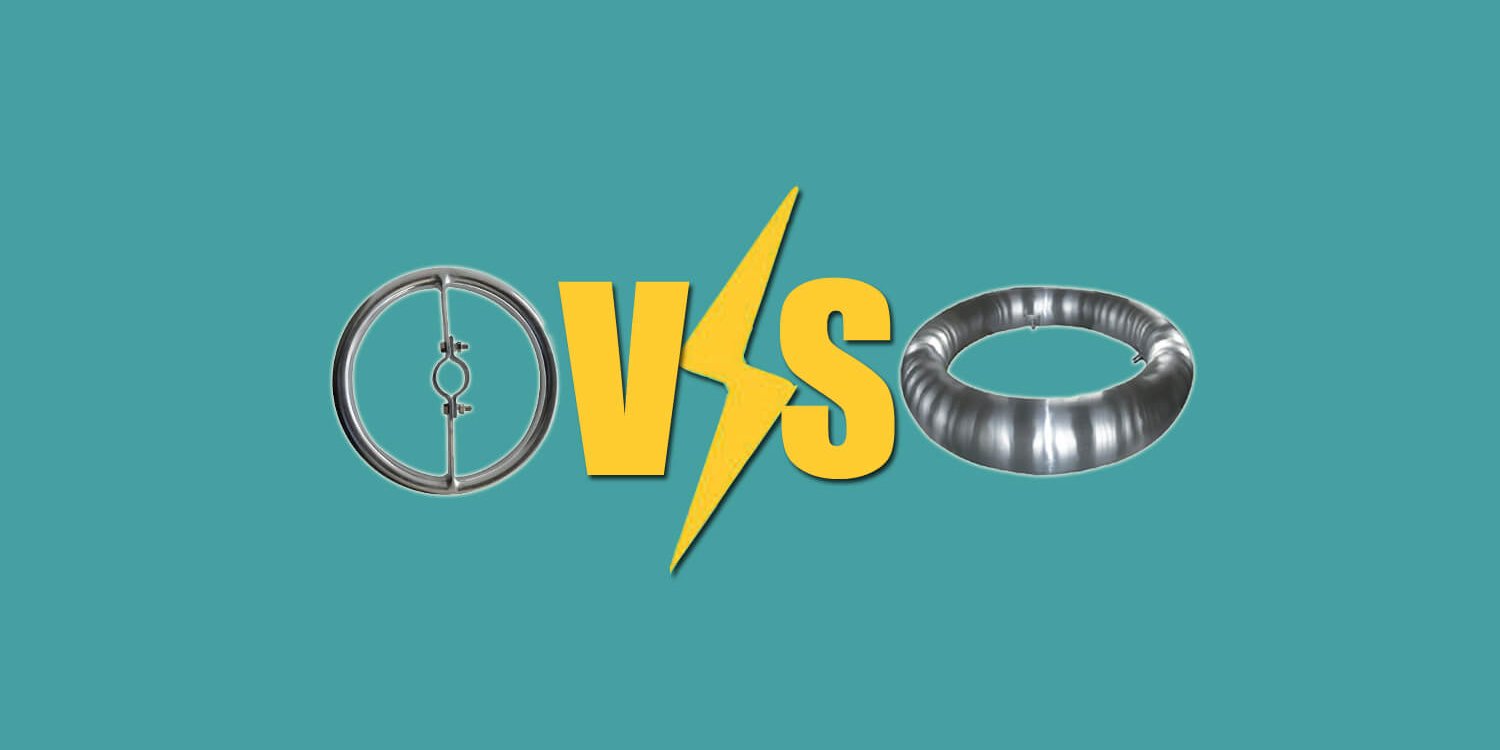

Grading rings and corona rings are common components in power transmission line and high voltage industry. They are easy to operate, convenient to move, and fast to install. Do you want to know difference between grading ring and corona ring? The below detailed contents gives a quick acquaintance for difference between them.

Brief Introduction

Grading ring is very similar to corona ring. Grading ring and corona ring are designed and produced for high voltage industry. The difference is due to their main purpose of application and their installation position. Grading rings is used around insulators to reduce the potential gradient. So grading rings improve the string efficiency and prevent insulation breakdown.

The corona ring is also called corona control ring or corona shielding ring. At sharp point (like bushing head) the electric field is high which results in corona. Aluminum corona ring ( shielding ring) should be installed at this point to suppresses the corona.

Grading Ring And Corona Ring Application

Grading rings are widely used in transmission lines and substations. According to manufacturing process, the grading ring can be divided into two types, pipe bending ring and pressure die casting ring. Meanwhile, in a lot of lightning arrester application, often used aluminum grading rings.

Corona rings are also known as anti corona rings, which are widely used in high voltage measuring equipments and power systems (gas insulated switchgear, high voltage transmission line, impulse voltage generator, etc.) and are mainly made of aluminum alloy. The corona ring can be divided into two types, single ring and phase to earth one. Meanwhile, in transformer bushing industry, often used aluminum corona rings.

Grading Ring And Corona Ring Design Parameters

Grading ring and corona ring design process is the basic and important part on high voltage project.

At first, you should know what the material is available and which is ring application. Here in China, there are two main production process categories. One method is called pipe bending, another one is called pressure die casting. According to real production process, the right aluminum material will be used for them. Cast aluminum 101A grade is good for pressure die casting grading ring production. Aluminum 6061, 6063 and 3A21 grade are popular for pipe bending ring production.

Second, you should understand what application of grading ring and corona ring you need. Grading ring is used in surge arresters. And corona ring is supplied to so many high voltage industries.

Third, the diameter of ring body should be considered, which have the main influence for potential gradient and corona effect. Some end users need super larger diameter rings for high voltage testing. We have to mention it that our processing capacity of corona ring diameter is up to 16000mm. Here in Highv, you can find every ring and corona solutions you like. Other installed parts such as brackets, support plate, head connecting tube and fasteners, etc. These are also the parameters in grading ring and corona ring design. Different grading rings and corona rings will be supplied to each operating voltage.

Last but not least, after the detailed drawings are confirmed by customers and Highv technical team. Then our workers will operate advanced equipment to produce rings quickly. During the production process, our team will check the sizes frequently and input record. This could ensure all corona rings good quality. Sometimes other surface treatment will be needed, just provide your idea.

Highv is a leading quality high voltage corona rings and metal fabrication expert. Supplying effective shielding solutions for power&industry, including shielding rings, shielding covers, shielding tubes, shielding spheres and GIS components. Call us or email us for more discounts for your projects.