Product Name: Aluminum Spinning Spare Part

Material: Aluminum

Size: Customized Size

OEM/ODM: Available

Metal spinning is a forming process that produces hollow parts that are typically circular in cross-section. The basic metal spinning process starts with a flat metal disc (blank), which rotates on a lathe. This rotating blank is pressed against a tool (chuck mandrel) that duplicates the interior of the part.

Historically metal spinning was associated with prototypes and low volume production time. However, with the introduction of automatic and CNC lathes metal spinning is now a cost-effective option for both medium and high volume production. The relatively inexpensive tooling price still makes this forming method a cost effective one for fabricating prototypes.

Raw Material:

- Aluminum Alloy 6061

- Aluminum Alloy 6063

- Aluminum Alloy 6082

- Aluminum 1060

- Aluminum 1070

- Other Aluminum

Application:

- Aerospace

- Textile Machinery

- Electrical Equipments

- HVDC System

- Others

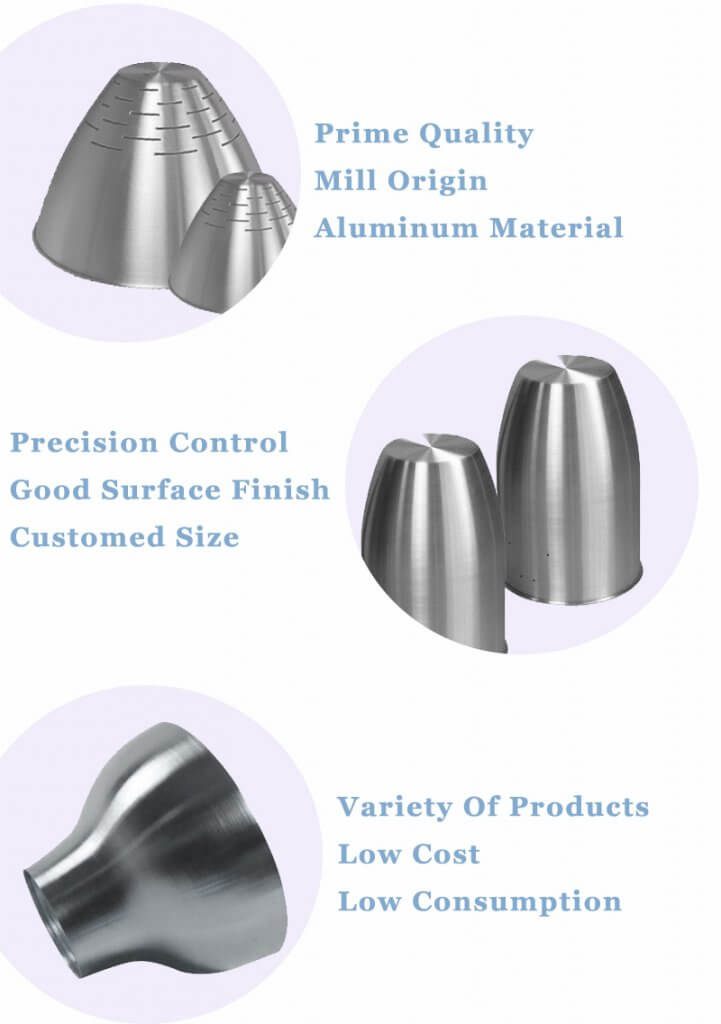

Aluminum Spinning Spare Part Showcase:

Advantages Of Aluminum Spinning Spare Part:

- High Quality: The surface roughness is low and the dimension tolerance is small.

- Low Consumption: The total deformation force required is small. greatly reducing the attack rate consumption. The tonnage of rotary press machine is only about 1/20 of that of press machine.

- Variety Of Products: The products range is wide, according to the rotary press capacity can be made large diameter thin-wall pipe, special pipe, variable section pipe and so on.

- Low Cost: High material utilization and low production cost. Compared with CNC machining, rotary press can save 20%-50% of materials, up to 80%, and reduce the cost by 30%-70%.

- Advanced Processing Production Equipment: Which can support you competitive price to support every different aluminum products regardless of the samples or mass production.

Quality Is Our Company Soul:

We pay more attention to quality support, supply scope, inspection, testing standard, shipment packing, after-sales service.

We have passed ISO9001 quality management system certification.

Quality Control Process:

1) Checking the raw material after they reach our factory- Incoming quality control

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production-In process quality control

4) Checking the goods after they are produced- Final quality control

5) Checking the goods before shipment

Packaging&Shipping:

Fine and safe packaging used for your aluminum spinning spare parts to assure no any damages during transportation.

1. Standard export packaging:

EPE+Poly Bags+Carton Box/Wooden Pallet or Wooden Case;

2. Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

3. Other special packaging will be designed as customer’s request;

4. By International Express: DHL/UPS/FEDEX/EMS and our own express line;

5. By air or By sea.

Our Services Process:

- Quotation: We promise your inquiry of your products can be quoted within 6 hours as long as we confirm your drawing and requirements.

- Sample Making: If aluminum parts no need new design moulds, samples can made within 10 days, fastest 3 days. If need new moulds, it normally takes around 25 days to make moulds and samples.

- Mass Production: During production of aluminum spinning spare parts, we can give you updates by sending you real pictures and videos.

- Assembly and Packaging: We can help you assemble the whole goods if you need. Packaging assure to be 100% safe and stable, because our packing department is professional and hardworking.

- After-sales Service: Once you receive the products, please open the packaging and check all cargo within 7 days. If there are quality issues, we will arrange to remake or return money for you. Highv team will do the best to meet all your satisfaction.

- Technical Support Highv is professional at independent development and design. Our professional engineers team are skilled at AUTO CAD, PROE, SOLID WORKS and UG softwares. We are able to design, develop, produce and deliver your order according to your detailed drawings, samples or just an idea.