Product Name: Stainless Steel Banding Strap

Packing: Plastic Dispenser or Carton Box

Material: 201/304/316

Stainless Steel Banding Strap Specification

Product Feature:

1. Polishing shiny finish and no scratch, safety round edge

2. Easy handling

3. High strength

4. Good resistance to oxidation and many moderate corrosive agents

5. Different length according to the request

Product Description:

Material | Stainless Steel Steel ASTM Grade 201/304/316 |

Thickness(mm) | 0.40/0.50/0.60/0.70/0.8/1.0 |

Thickness(inch) | 0.015’’,0.020’’,0.025’’,0.030’’,0.032’’,0.040’’ or as customer’s requests |

Width(mm) | 6.35/9.5/12.7/16/19/25.4/31.8 |

Width(inch) | 1/4’’,3/8’’,1/2’’,5/8’’,3/4’’,1’’,1 1/4’’ or as customer’s requests |

Length/Roll(meters) | 25/30.5/50 |

Vickers Hardness | 304/316(150HV-180HV), 201(190HV-220HV) |

Advantages | Stainless steel banding strap in a polishing shiny finish, offers good resistance to oxidation and many moderate corrosive agents. All our banding strap products are with many choice width and safety round edge for installation |

Package | Carton box, plastic dispenser or as customer’s requests |

Application | To bundle the pipes, tubes, cables, hydraulic hose, road signs, traffic lights, etc |

Delivery time | 15-20 working days |

MOQ | 10 rolls |

Loading Port | Shanghai port or Ningbo port |

Sample | The sample of stainless steel banding strap is available |

Chemical Composition&Mechanical Properties:

Grade | Chemical Composition | Mechanical Properties | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | N | Cu | Y.S | T.S | EL | HV |

% | % | % | % | % | % | % | % | % | Mpa | Mpa | % |

| |

Chinese 201 | ≤ 0.15 | ≤ 0.80 | 8.5~11 | ≤ 0.060 | ≤ 0.030 | 0.8~1.5 | 13.5~17 | ≤ 0.20 | 0.5~2 | ≥ 205

| ≥ 520 | ≥ 35 | ≤ 220 |

ASTM 201 | ≤ 0.08 | ≤ 0.75 | 7~9 | ≤ 0.060 | ≤ 0.010 | 4.0~4.5 | 14.5~17 | ≤ 0.15 | 1.5~1.7 | ≥ 260 | ≥ 620 | ≥ 40 | ≤ 220 |

The specification of type 201 according with mill standard | |||||||||||||

Grade | Chemical Composition | Mechanical Properties | ||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Y.S | T.S | EL | HV |

% | % | % | % | % | % | % | % | N/mm2 | N/mm2 | % |

| |

304 | ≤ 0.08 | ≤ 0.75 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 8~10 | 18~20 | – | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 180 |

316 | ≤ 0.08 | ≤ 1.00 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 10~14 | 16~18 | 2~3 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 180 |

316L | ≤ 0.03 | ≤ 1.00 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 12~15 | 16~18 | 2~3 | ≥ 170 | ≥ 480 | ≥ 40 | ≤ 180 |

The specification of type 304, 316, 316L according with ASTM standard | ||||||||||||

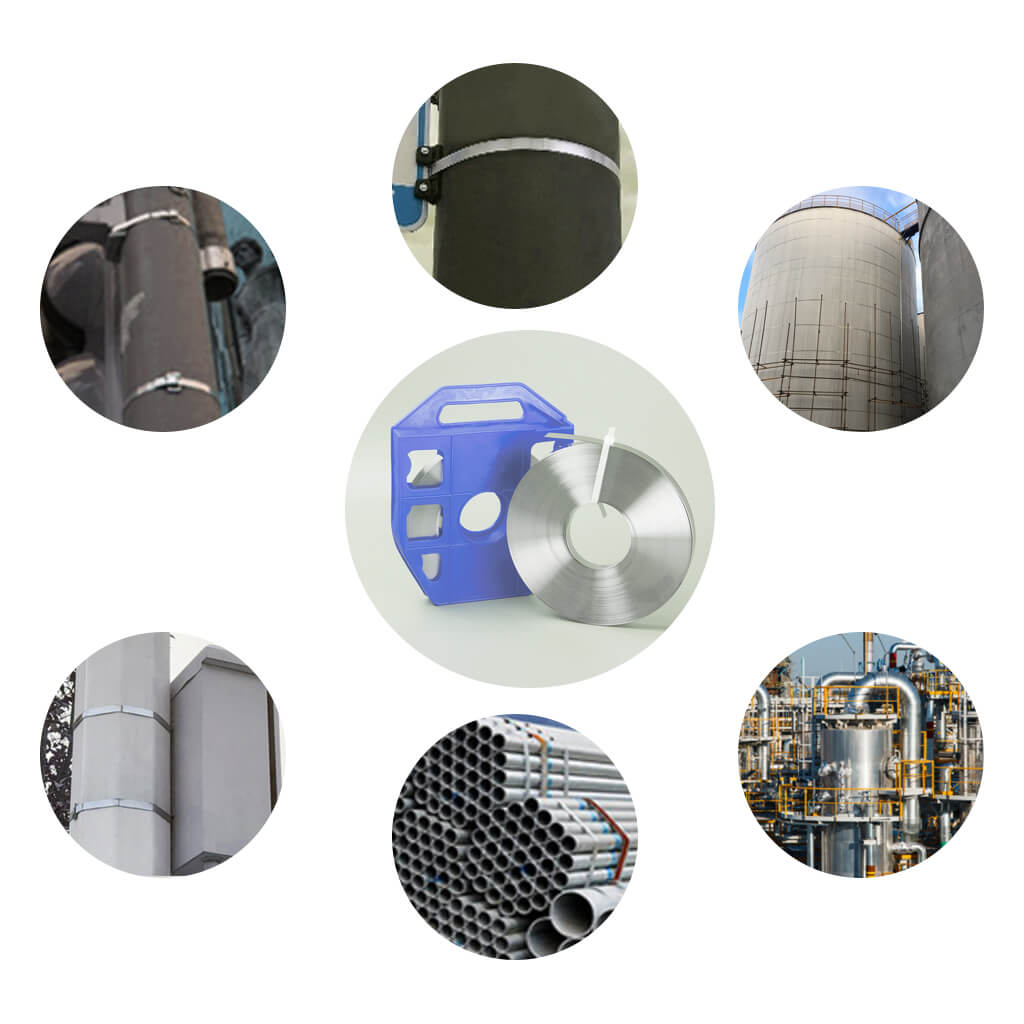

Stainless Steel Banding Strap Application

To bundle the pipes, tubes, cables, hydraulic hose, road signs, traffic lights, etc.

- Grade 201 stainless steel banding strap has superior yield and tensile strength properties to provide maximun clamping strength for different application. As you know, 201 vickers hardness is above 190HV. And 304 or 316 grade hardness is range from 150HV to 180HV.

- Grade 304 stainless steel banding strap are most common used and can be applied in almost any environment.

- Grade 316 stainless steel banding strap are specialized for seaside cities or extreme corrosive enviroment, such as the chemical factory or oil field application.

More Details

1. Product Name: stainless steel banding strap

2. Material: 201/304/316 grade stainless steel

3. Operating Temperature: -80° C-538° C

4. Stainless steel banding strap in a polishing shiny finish, offers good resistance to oxidation and many moderate corrosive agents

5. High tensile strength

Q1: Do you provide samples? Is it free or extra?

A1: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q2: Do you have a MOQ?

A2: Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell or use but in much smaller quantities, 10 rolls is ok.

Q3: Can you accept OEM?

A3: Yes, we have independent developing team. If your quantity is large, it is no problem to do OEM for you.

Q4: Can you supply the relevant technical documents?

A4: Of course we can, provide most documentation including certificates of analysis, test certificate, insurance copy, MTC, and other export documents where required.

Q5: What is the average leading time?

A5: For samples, the lead time is around 5 days. For mass production, the lead time is 15-25 working days after receiving deposit payment.

Q6: What kinds of payment methods do you accept?

A6: 30% deposit in advance, 70% balance before shipment.

Q7: Do you guarantee safety and secure delivery time of products?

A7: Yes, we always use high quality export packaging for avoid the damage of transport. We have detailed production plan sechdule list for making sure customer’s delivery time.

Q8: How about the shipping fees?

A8: The shipping cost depends on the methods you choose to get the cargo. International express is the most quickest for light weight but also most expensive way. By sea shipment is the best solution for large heavy weight goods. Exactly shipping rates we can give you with the quotation.