No matter what industry you are in, choosing the right material is one of the basic component in determining the overall function and practical benefits of your project.

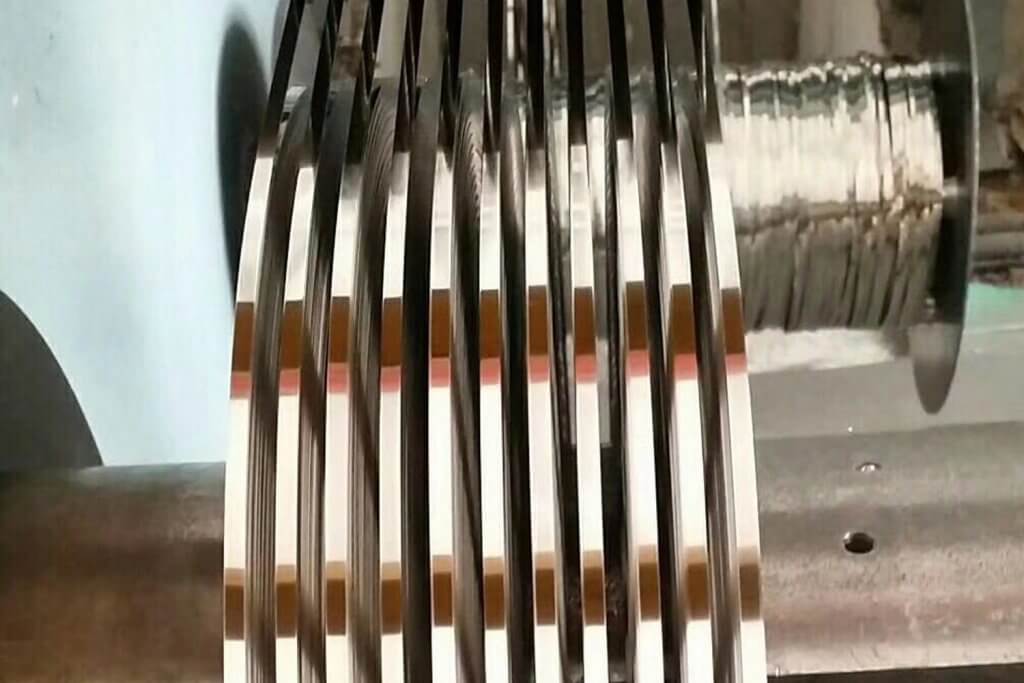

Two factors that cannot be ignored when using the stainless steel banding strap. They are application environment and material strength itself. SUS201, SUS304, SUS316 grade stainless steel material are common ones for banding strap production.

Here below article is the detailed introduction for choosing the right material of banding strapping!

Grade 201 that contains higher amounts of manganese and nitrogen and lower amounts of nickel than grade 304. This combination of elements reduces cost, increases mechanical strength and makes grade 201 work harden at a faster rate than grade 304 material.

As you know, 201 vickers hardness is above 190HV. And 304 or 316 grade hardness is range from 150HV to 180HV. But grade 201 material performs slightly below grade 304 in terms of corrosion and oxidation resistance.

Grade 201 stainless steel banding strap has superior yield and tensile strength properties to provide maximun clamping strength for different application.

Using 304 stainless steel material is a smart choice for your banding strap project and longevity. It is cost-effective in comparison to other stainless steel materials. Grade 304 material’s high quality and durability ensures that your product lasts a long time and the production of it is suitable for almost industry use.

304 Stainless steel has excellent corrosion resistance and good resistance to intergranular corrosion. At -180 ℃ low temperature condition, strength, elongation, area reduction rate is very good. In the absence of brittle transition temperature, It is also often used at low temperatures.

SUS316 stainless steel material, is a popular grade of stainless steel where superior corrosion resistance is of primary importance. Grade 316 stainless steel is widely used in marine and highly acidic environments applications. The addition of molybdenum increases the corrosion resistance of 316 stainless steel over the more economical SUS304 grade. Grade 316 stainless steel banding strap are specialized for seaside cities or extreme corrosive environment, such as the chemical factory or oil field application.

These above are only the three main kinds of materials for stainless steel banding strapping production, Highv offered complete stainless steel banding solutions.

For more information, kindly browse our website or contact us at any time.